Popular keywords: Electric hoist, European style crane, lightweight customized crane

Product introduction Double rope | double lifting point electric hoist detailed introduction Double lifting point electric hoist is also known as: double hook electric hoist, electric hoist with the same lift and fall, synchronous shaft electric hoist, connected double hook ele...

400-966-5869

Product introduction

Double rope | double lifting point electric hoist detailed introduction

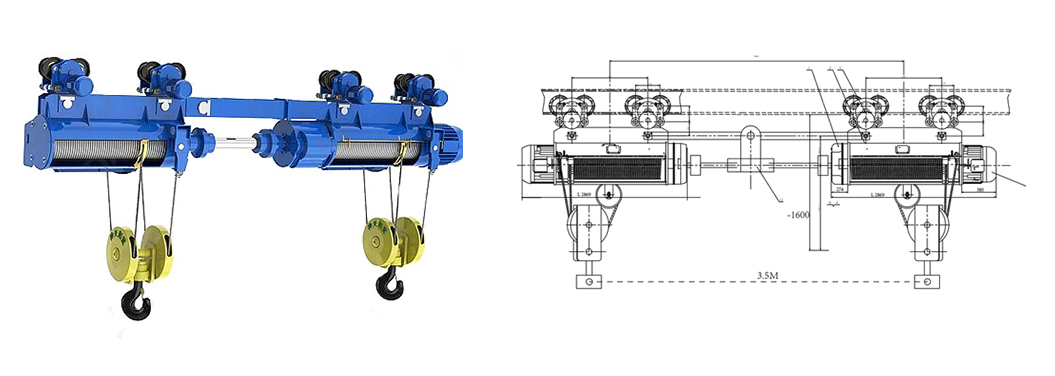

Double lifting point electric hoist is also known as: double hook electric hoist, electric hoist with the same lift and fall, synchronous shaft electric hoist, connected double hook electric hoist, double hook electric hoist with the same barrel, double hook synchronous wire rope electric hoist, double hook synchronous electric hoist, gate electric hoist. Coaxial double-hook two-speed electric hoist is a two-speed wire rope electric hoist connected by a drive shaft.

Double lifting point electric hoist Detailed description:

Double lifting point electric hoist is suitable for lifting long workpieces or articles. Hook distance can be made according to user requirements non-standard design. The intermediate drive shaft is used to connect the two upper hoists to achieve the same rise and fall. When the wire rope electric hoist is lifting and falling, the rope will be wrapped or lowered along the rope groove on the drum, and the double hook will be moving to the side at the same time when it is rising and falling. The larger the vertical height of the lifting object from the installation position of the hoist, the smaller the translation amplitude. For example, the lifting object is on the ground, and the hoist is installed at a height of 12 meters above the ground. When the hook is raised to its maximum limit, it is 11 meters from the ground. Using a hoist with a lifting height of 12 meters to lift objects on the ground, when it comes to a height of 6 meters, the horizontal movement is very small. That is, the installation position of the hoist must be a few meters above the target position of the lifting object, and the greater the distance, the smaller the horizontal movement.

The equipment through mechanical and electrical synchronization, forcing the speed of the lifting motor synchronization, two electric hoists use a set of electrical control system to overcome the electrical action error, so as to ensure that two electric hoists lift and lift heavy objects at the same time. The equipment combination is convenient, and auxiliary functions such as overload limit, height display and remote control can be added.

Coaxial double hook double speed electric hoist:

That is, the two hoists connected by the drive shaft are two-speed wire rope electric hoists. Suitable for lifting long workpieces or articles. Hook distance can be made according to user requirements non-standard design. Double hook wire rope electric hoist is customized products, if you need to negotiate the specific parameters, please call us.

Lifting weight: 16 t, 10 t, 2 * 2 * 2 * 32 t lifting height: H = 6 M – 24 M hook distance: 1.2 M or less L 7 M or less

The intermediate drive shaft is used to connect the two upper hoists to achieve the same rise and fall. When the wire rope electric hoist is lifting and falling, the rope will be wrapped or lowered along the rope groove on the drum, and the double hook will be moving to the side at the same time when it is rising and falling. The larger the vertical height of the lifting object from the installation position of the hoist, the smaller the translation amplitude. For example, the lifting object is on the ground, and the hoist is installed at a height of 12 meters above the ground. When the hook is raised to its maximum limit, it is 11 meters from the ground. Using a hoist with a lifting height of 12 meters to lift objects on the ground, when it comes to a height of 6 meters, the horizontal movement is very small. That is, the installation position of the hoist must be a few meters above the target position of the lifting object, and the greater the distance, the smaller the horizontal movement.

| ZMCD, ZMMD series electric hoist technical performance and dimensions (0.25T-20T) | |||||||||||||||||||||||||||

| Model | ZMCD1 ZMMD1 | ||||||||||||||||||||||||||

| Lifting weight | tons | 0.25 | 0.5 | 1 | 2 | 3 | |||||||||||||||||||||

| Lifting height | m | 3 | 6 | 9 | 6 | 9 | 12 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | ||

| Lifting speed | m/min | 8 | 8/0.8 | 8/0.8 | 8/0.8 | 8/0.8 | |||||||||||||||||||||

| Running speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | |||||||||||||||||||||

| Wire Rope | Rope diameter | mm | 3.6 | 4.8 | 7.4 | 11 | 13 | ||||||||||||||||||||

| Wire diameter | mm | 0.22 | 0.34 | 0.5 | 0.6 | ||||||||||||||||||||||

| Structure form | 6×9 | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | ||||||||||||||||||||||

| I-beam track Model (GB76-88) | 16-22b | 16-28b | 16-28b | 20a-32c | 20a-32c | ||||||||||||||||||||||

| Minimum radius of ring track | m | 0.8 | 1.5 | 1.5 | 2 | 3 | 4 | 2 | 2.5 | 3 | 4 | 2 | 2.5 | 3 | 4 | ||||||||||||

| Lifting motor | Model | ZD12-4 | ZD21-4 | ZD21-4 | ZD31-4 | ZD41-4 | |||||||||||||||||||||

| Capacity | kW | 0.4 | 0.8 0.2/0.8 | ||||||||||||||||||||||||

| Speed | RPM | 1380 | 1380 | 1380 | 1380 | 1380 | |||||||||||||||||||||

| Number of phases | 3 | 3 | 3 | 3 | 3 | ||||||||||||||||||||||

| Voltage | Volts | 380 | 380 | 380 | 380 | 380 | |||||||||||||||||||||

| Current | Amperes | 1.25 | 2.4 0.72/2.4 | 4.3 0.72/4.3 | 7.6 1.25/7.6 | 11 2.4/11 | |||||||||||||||||||||

| Frequency | weeks/second | 50 | 50 | 50 | 50 | 50 | |||||||||||||||||||||

| Run the motor | Model | DW5024 | ZDY11-4 | ZDY12-4 | ZD12-4 | ZDY21-4 | |||||||||||||||||||||

| Capacity | kW | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | |||||||||||||||||||||

| Speed | RPM | 1400 | 1380 | 1380 | 1380 | 1380 | |||||||||||||||||||||

| Number of phases | 3 | 3 | 3 | 3 | 3 | ||||||||||||||||||||||

| Voltage | Volts | 380 | 380 | 380 | 380 | 380 | |||||||||||||||||||||

| Current | Amperes | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | |||||||||||||||||||||

| Frequency | weeks/second | 50 | 50 | 50 | 50 | 50 | |||||||||||||||||||||

| Job Type and organization level | Intermediate M3 | Intermediate M3 | Intermediate M3 | Intermediate M3 | Intermediate M3 | ||||||||||||||||||||||

| Base Size ±2% | H | Millim | 432 | 630 | 670 | 685 | 780 | 860 | 960 | 985 | 1080 | ||||||||||||||||

| L2 | M | 216 | 126 | 159 | 187 | 230 | |||||||||||||||||||||

| L1 | 175 | 228/225 | 269/266 | 279 | 341/343 | ||||||||||||||||||||||

| L | C | 391 | 616 | 688 | 760 | 758 | 856 | 955 | 1150 | 1346 | 1542 | 820 | 920 | 1020 | 1220 | 1420 | 1620 | 915 | 1018 | 1121 | 1327 | 1533 | 1738 | ||||

| M | 638 | 710 | 782 | 780 | 878 | 976 | 1172 | 1368 | 1564 | ||||||||||||||||||

| m | 104 | 318 | 390 | 462 | 400 | 499 | 597 | 793 | 989 | 1185 | 418 | 518 | 618 | 818 | 1018 | 1218 | 448 | 551 | 654 | 860 | 1066 | 1272 | |||||

| n | 130 | 190 | 196 | 240 | 264 | ||||||||||||||||||||||

| h | 120 | 124 | 155 | 173 | |||||||||||||||||||||||

| φ | 16.5 | 16.5 | 19 | 25 | 25 | ||||||||||||||||||||||

| B | 279-315 | -884 | -884 | -930 | -930 | ||||||||||||||||||||||

| E | 395 | 490 | 584 | 740 | 848 | ||||||||||||||||||||||

| F | 355/426 | 354/492 | 400/562 | 438/642 | |||||||||||||||||||||||

| Total ±15% | C | Public | 44 | 44.4 | 44.8 | 120 | 125 | 145 | 145 | 158 | 180 | 195 | 208 | 222 | 235 | 248 | 296 | 320 | 340 | 360 | 280 | 300 | 350 | 380 | 405 | 435 | |

| M | Catty | 135 | 140 | 160 | 160 | 170 | 200 | 210 | 220 | 230 | 265 | 278 | 326 | 350 | 370 | 310 | 310 | 330 | 380 | 410 | 435 | 465 | |||||

| C solid | 30 | 30.4 | 30.8 | 80 | 85 | 90 | 120 | 120 | 125 | 140 | 150 | 165 | 168 | 180 | 190 | 210 | 230 | 250 | 220 | 235 | 250 | 275 | 300 | 325 | |||

| M solid | 100 | 105 | 110 | 130 | 140 | 145 | 155 | 165 | 180 | 196 | 210 | 220 | 240 | 260 | 280 | 250 | 265 | 280 | 305 | 330 | 355 | ||||||

| ZMCD, ZMMD series electric hoist technical performance and dimensions (0.25T-20T) | ||||||||||||||

| Model | ZMCD1 | ZMMD1 | ||||||||||||

| Lifting weight | tons | 5 | 10 | |||||||||||

| Lifting height | m | 6 | 9 | 12 | 18 | 24 | 30 | 9 | 12 | 18 | 24 | 30 | ||

| Lifting speed | m/min | 8/0.8 | 7/0.7 | |||||||||||

| Running speed | m/min | 20(30) | 20(30) | |||||||||||

| Wire Rope | Rope diameter | mm | 15 | 15 | ||||||||||

| Wire diameter | mm | 0.7 | 0.7 | |||||||||||

| Structure form | D-6×37+1 | D-6×37+1 | ||||||||||||

| I-beam track Model (GB76-88) | 25a-63c | 25a-63c | ||||||||||||

| Minimum radius of ring track | m | 2.5 | 3 | 4 | 5 | 2.5 | 3.5 | 4 | 6 | 9 | ||||

| Lifting motor | Model | ZD41-4 | ZD51-4 | |||||||||||

| Capacity | kW | |||||||||||||

| Speed | RPM | 1380 | 1380 | |||||||||||

| Number of phases | 3 | 3 | ||||||||||||

| Voltage | Volts | 380 | 380 | |||||||||||

| Current | Amperes | 18 2.4/18 | 30 4.3/30 | |||||||||||

| Frequency | weeks/second | 50 | 50 | |||||||||||

| Run the motor | Model | ZDY21-4 | ZDY21-4 | |||||||||||

| Capacity | kW | 0.8 | 0.8×2 | |||||||||||

| Speed | RPM | 1380 | 1380 | |||||||||||

| Number of phases | 3 | 3 | ||||||||||||

| Voltage | Volts | 380 | 380 | |||||||||||

| Current | Amperes | 2.4 | 2.4×2 | |||||||||||

| Frequency | weeks/second | 50 | 50 | |||||||||||

| Job Type and organization level | Intermediate M3 | Intermediate M3 | ||||||||||||

| Base Size ±2% | H | Millim | 1160 | 1310 | 1350 | |||||||||

| L2 | M | 274 | 303 | |||||||||||

| L1 | 380/377 | 429/820 | ||||||||||||

| L | C | 1047 | 1157 | 1257 | 1467 | 1677 | 1887 | 1602 | 1783 | 2145 | 2507 | 1869 | ||

| M | 1059 | 1169 | 1269 | 1479 | 1682 | 1899 | 1969 | 2150 | 2512 | 2874 | 3236 | |||

| m | 485 | 606 | 695 | 860 | 1115 | 1325 | 949 | 1130 | 1492 | 1854 | 2216 | |||

| n | 320 | 376 | ||||||||||||

| h | 203 | 243 | ||||||||||||

| φ | 31 | 37 | ||||||||||||

| B | -1058 | -1058 | ||||||||||||

| E | 998 | 1068 | ||||||||||||

| F | 472/675 | 612 | ||||||||||||

| Total ±15% | C | Public | 445 | 470 | 555 | 590 | 630 | 670 | 1010 | 1063 | 1166 | 1263 | 1317 | |

| M | Catty | 480 | 505 | 590 | 630 | 660 | 705 | 1100 | 1153 | 1256 | 1353 | 1407 | ||

| C solid | 355 | 375 | 390 | 425 | 460 | 500 | 759 | 807 | 900 | 987 | 1032 | |||

| M solid | 390 | 410 | 425 | 460 | 500 | 535 | 849 | 897 | 990 | 1077 | 1122 | |||

| ZMCD, ZMMD series electric hoist technical performance and dimensions (0.25T-20T) | ||||||||||||||||

| Model | ZMCD | NH20-12D | ||||||||||||||

| Lifting weight | tons | 16 | 20 | 20 | 3 | |||||||||||

| Lifting height | m | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | |||

| Lifting speed | m/min | 3.5 3.5/0.35 | 3.5 3.5/0.35 | 5 | 8/0.8 | |||||||||||

| Running speed | m/min | 18 | 20 | 20 | 20(30) | |||||||||||

| Wire Rope | Rope diameter | mm | 15 | 17 | 22.5 | 13 | ||||||||||

| Wire diameter | mm | 0.7 | 0.8 | 0.6 | ||||||||||||

| Structure form | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | ||||||||||||

| I-beam track Model (GB76-88) | 45a-63c | 50a-63c | 20a-32c | |||||||||||||

| Minimum radius of ring track | m | 3 | 3.5 | 4.6 | 3 | 3.5 | 4.6 | 2 | 2.5 | 3 | 4 | |||||

| Lifting motor | Model | ZD51-4 | ZD51-4 | ZD41-4 | ||||||||||||

| Capacity | kW | |||||||||||||||

| Speed | RPM | 1380 | 1380 | 1380 | 1380 | |||||||||||

| Number of phases | 3 | 3 | 3 | 3 | ||||||||||||

| Voltage | Volts | 380 | 380 | 380 | 380 | |||||||||||

| Current | Amperes | 30 4.3/30 | 30 4.3/30 | 11 2.4/11 | ||||||||||||

| Frequency | weeks/second | 50 | 50 | 50 | 50 | |||||||||||

| Run the motor | Model | ZDY21-4 | ZDY21-4 | ZDY21-4 | ||||||||||||

| Capacity | kW | 0.8×2 | 0.8×2 | 0.8 x 2 | 0.4 | |||||||||||

| Speed | RPM | 1380 | 1380 | 1380 | 1380 | |||||||||||

| Number of phases | 3 | 3 | 3 | 3 | ||||||||||||

| Voltage | Volts | 380 | 380 | 380 | 380 | |||||||||||

| Current | Amperes | 2.4×2 | 2.4×2 | 2.4 x 2 | 1.25 | |||||||||||

| Frequency | weeks/second | 50 | 50 | 50 | 50 | |||||||||||

| Job Type and organization level | Intermediate M2 | Intermediate M2 | Intermediate M3 | |||||||||||||

| Base Size ±2% | H | Millim | 1600 | 2400 | 985 | 1080 | ||||||||||

| L2 | M | Same as 10t | 230 | |||||||||||||

| L1 | Same as 10t | 341/343 | ||||||||||||||

| L | C | Same as 10t | 915 | 1018 | 1121 | 1327 | 1533 | 1738 | ||||||||

| M | ||||||||||||||||

| m | 949 | 1130 | 1492 | 956 | 1478 | 1605 | 448 | 551 | 654 | 860 | 1066 | 1272 | ||||

| n | 376 | 376 | 264 | |||||||||||||

| h | 41 | 46 | 173 | |||||||||||||

| φ | 25 | |||||||||||||||

| B | -930 | |||||||||||||||

| E | 1335 | 1934 | 848 | |||||||||||||

| F | 1055 | 438/642 | ||||||||||||||

| Total ±15% | C | Public | 280 | 300 | 350 | 380 | 405 | 435 | ||||||||

| M | Catty | 310 | 330 | 380 | 410 | 435 | 465 | |||||||||

| C solid | 220 | 235 | 250 | 275 | 300 | 325 | ||||||||||

| M solid | 250 | 265 | 280 | 305 | 330 | 355 | ||||||||||