Popular keywords: Electric hoist, European style crane, lightweight customized crane

Product introduction The explosion-proof hand hoist is made of aluminum bronze and beryllium bronze as blanks, and the shell of the explosion-proof hand hoist is made of H62 copper alloy material. The rotating gear is heat-treated at high temperature to achieve high wear resista...

400-966-5869

Product introduction

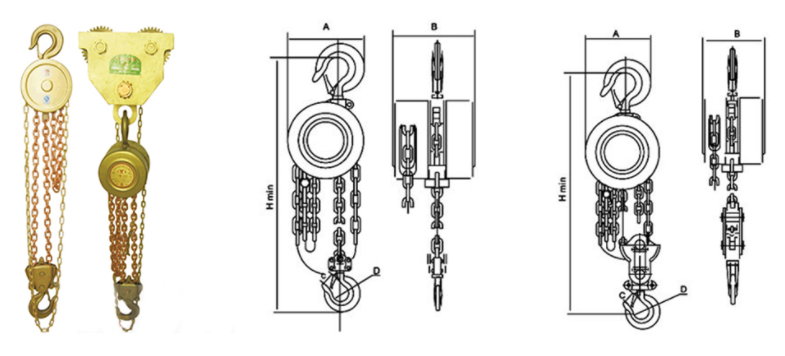

The explosion-proof hand hoist is made of aluminum bronze and beryllium bronze as blanks, and the shell of the explosion-proof hand hoist is made of H62 copper alloy material. The rotating gear is heat-treated at high temperature to achieve high wear resistance of the gear. In the operation of the product friction impact will not produce mechanical sparks, in flammable and explosive places do not detonate gas, effectively prevent fire accidents.

Working principle of explosion-proof hand hoist:

Through the tracer chain chain, the hand sprocket starts to rotate, the friction plate ratchet and the brake seat (are pressed into a body) rotate together, and the five-tooth long shaft turns the plate gear, the four-tooth short shaft and the spline hole gear. Thus, the lifting sprocket installed on the spline hole gear drives the lifting chain and smoothly lifts the heavy object.

Explosion-proof hand hoist is a kind of manual lifting machinery that is easy to use and easy to carry, with small tension and light weight, easy to carry, beautiful appearance, small size and durable.

Explosion-proof hand hoist can be used with explosion-proof manual monorail car to form a manual lifting transport car, explosion-proof hand hoist can be widely used in petroleum, petrochemical, oil station, oil depot, gas production, chemical industry, military, electric power, mining, electronics, railway, and other potential fire and explosion dangerous environment, in the operation of products friction impact will produce mechanical sparks. Effectively prevent fire accidents to ensure national property and personal safety. It is also an indispensable special tool for machinery manufacturing and machinery maintenance.

| Model | HBSQ-1/2 | HBSQ-1 | HBSQ-1 1/2 | HBSQ-2 | HBSQ-3 | HBSQ-5 | HBSQ-10 | HBSQ-20 | |

| Lifting weight (tons) | 0.5 | 1 | 1.5 | 2 | 3 | 5 | 10 | 20 | |

| Standard lifting height (m) | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3 | 3 | |

| Test load (tons) | 0.75 | 1.5 | 2.25 | 3 | 4.5 | 7.5 | 12.5 | 25 | |

| Minimum distance between two hooks (mm) | 270 | 270 | 368 | 444 | 486 | 616 | 700 | 1000 | |

| Full load bracelet tension (Newton) | 225 | 309 | 343 | 314 | 343 | 383 | 392 | 392 | |

| Number of hoisting lines | 1 | 1 | 1 | 2 | 2 | 2 | 4 | 8 | |

| Lifting chain round steel diameter (mm) | 6 | 6 | 8 | 6 | 8 | 10 | 10 | 10 | |

| Main Dimensions (mm) | A | 120 | 142 | 178 | 142 | 178 | 210 | 358 | 580 |

| B | 108 | 122 | 139 | 122 | 139 | 162 | 162 | 189 | |

| C | 24 | 28 | 34 | 34 | 38 | 48 | 64 | 82 | |

| D | 120 | 142 | 178 | 142 | 178 | 210 | 210 | 210 | |

| Net weight (kg) | 9.5 | 10 | 16 | 14 | 24 | 36 | 68 | 155 | |

| Gross weight (kg) | 12 | 13 | 20 | 17 | 28 | 45 | 83 | 193 | |

| Packing size (L x W x H) cm | 28X21X17 | 30X24X18 | 34X29X20 | 33X25X19 | 38X30X20 | 45X35X24 | 62X50X28 | 70X46X75 | |

| Lifting height increased by 1 m Increased weight (kg) |

1.7 | 1.7 | 2.3 | 2.5 | 3.7 | 5.3 | 9.7 | 19.4 |

|