Popular keywords: Electric hoist, European style crane, lightweight customized crane

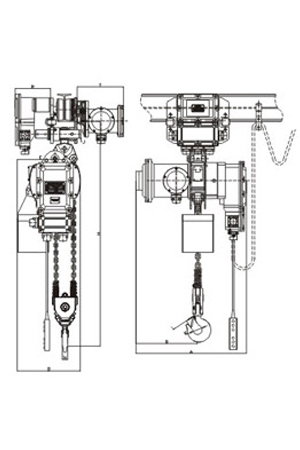

Product introduction BHH explosion-proof chain electric hoist Introduction: BHH type explosion-proof electric scraper low lifting height of the wire rope electric hoist the most ideal alternative. Generally installed on the overhead I-steel track, or suspended on the fixed fra...

400-966-5869

Product introduction

BHH explosion-proof chain electric hoist Introduction: BHH type explosion-proof electric scraper low lifting height of the wire rope electric hoist the most ideal alternative. Generally installed on the overhead I-steel track, or suspended on the fixed frame and special spadder to lift goods and equipment supporting to, etc., widely used in industrial, mountain warehouse, wharf, construction sites, shopping malls, hotels and other industries, especially suitable for low occasions and the existence of dust, damp decay gas and other environments. BHH type explosion-proof chain electric hoist is designed by referring to and absorbing the structural advantages of similar products at home and abroad, it not only has many advantages of foreign products, but also has the advantages of convenient maintenance, practical and reliable, low price, etc., so as to be more suitable for China’s actual national conditions.

Explosion-proof chain electric hoist advantages:

Explosion-proof chain electric hoist adopts the advanced structure of transmission, hanger and motor three parts of the axial assembly. This structure is not only easy to maintain, but also has a good sealing effect, especially suitable for outdoor and dusty occasions. The explosion-proof hoist is powered by China’s new type disc brake motor, which has the advantages of small size and reliable and sensitive braking, and the strength of the wear-resistant steel chain is stable and safe. It is the ideal small lifting tool.

Explosion-proof ring chain electric hoist use environment:

(1) Below 1000 meters above sea level.

(2) The air temperature in Zhou is not higher than +40’C, not lower than 20*C.

(3) Power grid fluctuation in soil 10%.

(4) The relative humidity does not exceed 959%, which can prevent dripping.

(5) Zone 1 or Zone 2 of the explosive environment of Class 11 B and T4 temperature groups in the factory.

Note: The product is strictly in accordance with the national 3 package, the product quality is insured by the People’s Insurance Company of China (PICC), please rest assured. Products strictly in accordance with the national 3 package implementation, product quality by the People’s Insurance Company of China (ICC) underwriting, please rest assured to use.

| Explosion-proof rating | Temperature level | |

| T1 | T2 | |

| d11A | Ethane, propane, styrene, xylene, CO, | Ethanol, butane, propylene, ethyl acetate, dioxyethane, chloroethylene |

| Acetone acetic acid, methyl acetate, ammonia, pyridine | Alkene, Thiophene, cyclic alcohol, dichloroethane, dimethylamine | |

| d11B | Propane, acrylonitrile, hydrogen cyanide, Coke oven gas | Ethylene, cyclopropanethane, acrylic acid, methyl ester, Furan |

| Natural temperature class Explosion-proof class | T1 | T2 |

| d11A | Ethane, Propane, Acetone Styrene, chlorinated styrene, chlorine | Ethanol, butane, propylene, butane acetate, acetic acid |

| Benzene, toluene, ammonia, carbon oxide, acetic acid, ethyl acetate | , acid, naphthenes, butanol | |

| d11B | Propyl, acrylonitrile | Oxethane, butadiene, butene |

| d11C | Hydrogen, water gas | Acetylene |

| Note: Technical performance table parameters refer to BCD, BMD | ||

| Explosion-proof rating | Temperature level | |

| T3 | T4 | |

| d11A | Alkyl, decane, ethyl naphthane, turpentine, naphtha, petroleum | Ethyl ether, acetaldehyde, trimethylamine |

| (including automotive oil, fuel oil) alcohol, chlorobutane, thiophene | ||

| d11B | Dimethyl ether, acrolein, tetrahydrofuran, hydrogen sulfide | |

| Natural temperature class Explosion-proof class | T3 | T4 |

| d11A | Alkyl, heptane, octane, decane, gasoline | Ethanol |

| d11B | Hydrogen sulfide, dimethyl ether | Diethyl ether, dibutyl ether |

| d11C | ||

| Note: Technical performance table parameters refer to BCD, BMD | ||

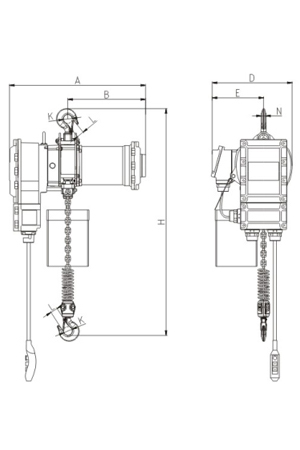

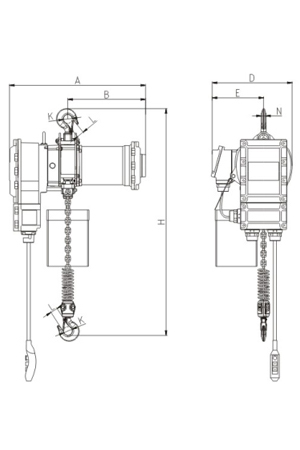

| Model | Rated load | Dimensions (mm) | |||||

| (T) | H | A | B | D | E | K | |

| HGBD01EP-01 | 1 | 600 | 600 | 330 | 300 | 176 | φ40 |

| HGBD02EP-02 | 2 | 750 | 600 | 330 | 300 | 230 | φ49 |

| HGBD03EP-03 | 3 | 920 | 600 | 330 | 350 | 280 | φ59 |

| HGBD03EP-01 | 3 | 845 | 675 | 325 | 430 | 265 | φ59 |

| HGBD03EP-02 | 3 | 950 | 675 | 325 | 430 | 320 | φ59 |

| HGBD05EP-02 | 5 | 1030 | 675 | 325 | 430 | 325 | φ60 |

| HGBD7.5EP-03 | 7.5 | 1200 | 675 | 325 | 500 | 320 | φ90 |

| HGBD10EP-04 | 10 | 1400 | 725 | 350 | 890 | 445 | φ90 |

| HGBD15EP-06 | 15 | 1360 | 725 | 350 | 1030 | – | φ110 |

| HGBD20EP-08 | 20 | 1250 | 725 | 350 | 1220 | – | φ110 |

| HGBD25EP-10 | 25 | 1700 | 725 | 350 | 1315 | – | φ140 |

| HGBD30EP-12 | 30 | 1640 | 915 | 458 | 1380 | – | φ140 |

| HGBD35EP-16 | 35 | 1790 | 915 | 458 | 1600 | – | φ200 |

| Model | Rated load | Size (mm) | ||||

| L | N | M | J | Q | Chain | |

| HGBD01EP-01 | 31 | 24 | – | – | – | φ7.1 |

| HGBD02EP-02 | 35 | 30 | – | – | – | φ7.1 |

| HGBD03EP-03 | 42 | 35 | – | – | – | φ7.1 |

| HGBD03EP-01 | 42 | 35 | – | – | – | φ11.2 |

| HGBD03EP-02 | 42 | 35 | – | – | – | φ10.0 |

| HGBD05EP-02 | 45 | 43 | – | – | – | φ11.2 |

| HGBD7.5EP-03 | 70 | 50 | – | – | – | φ11.2 |

| HGBD10EP-04 | 70 | 50 | – | – | – | φ11.2 |

| HGBD15EP-06 | 80 | 85 | 88 | φ70 | 520 | φ11.2 |

| HGBD20EP-08 | 80 | 85 | 88 | φ70 | – | φ11.2 |

| HGBD25EP-10 | 100 | 95 | 96 | φ80 | – | φ11.2 |

| HGBD30EP-12 | 100 | 95 | 228 | φ90 | – | φ11.2 |

| HGBD35EP-16 | 140 | 135 | 235 | φ100 | 440 | φ11.2 |