Popular keywords: Electric hoist, European style crane, lightweight customized crane

Product introduction Stainless steel hoist with safe and reliable, easy maintenance, high mechanical efficiency, bracelet tension is small, light weight to carry, beautiful appearance, small size, durable characteristics, stainless steel hoist is suitable for factories, mines, c...

400-966-5869

Product introduction

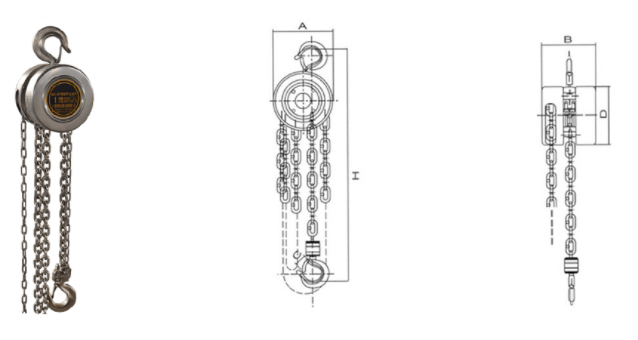

Stainless steel hoist with safe and reliable, easy maintenance, high mechanical efficiency, bracelet tension is small, light weight to carry, beautiful appearance, small size, durable characteristics, stainless steel hoist is suitable for factories, mines, construction sites, docks, shipyards, warehouses and other used as installation machinery, lifting goods, especially for open air and no power operations, but also show the superiority.

Stainless steel hand hoist is made of 304 material, because of the particularity of its material, so that it has some special functions, such as good rust resistance, high temperature resistance, corrosion resistance and other properties. Stainless steel hand hoist can be used in factories, mines, agriculture, electricity, construction production and construction, dock, dock and other places of machine installation, cargo lifting, vehicle loading and unloading work, especially for food processing, chemical industry and other places, the most widely used. In addition, we can meet the customized needs of users, so that the overall situation of the hand hoist is more in line with the needs of users, convenient for users to work and use.

Stainless steel hand hoist advantages:

1, the whole machine is made of stainless steel, after high temperature quenching supply forging;

2, corrosion resistance, wear resistance, high temperature resistance, low temperature resistance;

3, high degree of cleanliness;

| Model | HSZ – 0.5 – A | HSZ-1A | HSZ – 1.5 – A | HSZ-2A | HSZ-3A | HSZ-5A | HSZ – 7.5 – A | HSZ-10A | HSZ-15A | HSZ-20A | HSZ-30A | HSZ-50A | |

| Lifting weight (tons) | 0.5 | 1 | 1.5 | 2 | 3 | 5 | 7.5 | 10 | 15 | 20 | 30 | 50 | |

| Standard lifting height (m) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Test load (tons) | 6.3 | 12.5 | 18.8 | 25 | 37.5 | 62.5 | 94 | 125 | 187.5 | 250 | 375 | 625 | |

| Full load bracelet tension (Newton) | 231 | 309 | 320 | 320 | 360 | 414 | 420 | 420 | 430 | 420*2 | 450*2 | 450*2 | |

| Number of hoisting lines | 1 | 1 | 1 | 1 | 2 | 2 | 3 | 4 | 6 | 8 | 12 | 22 | |

| Lifting chain round steel diameter (mm) | 5 | 6 | 7.1 | 8 | 7.1 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | |

| Main Dimensions (mm) | A | 115 | 143 | 148 | 152 | 148 | 181 | 181 | 181 | 181 | 192 | 330 | 410 |

| B | 136 | 156 | 182 | 198 | 182 | 266 | 365 | 365 | 485 | 630 | 670 | 965 | |

| C | 270 | 317 | 399 | 414 | 465 | 636 | 798 | 798 | 920 | 890 | 1000 | 1950 | |

| D | 25 | 27 | 34 | 36 | 38 | 48 | 57 | 57 | 84 | 84 | 84 | 130 | |

| Net weight (kg) | 8 | 11 | 17 | 18 | 22 | 45 | 52 | 70 | 125 | 162 | 228 | 1085 | |

| Lifting weight per 1 m Increased weight (kg) |

1.5 | 1.8 | 2.1 | 2.3 | 4.2 | 5.6 | 7.3 | 9.8 | 14.2 | 19.6 | 28.3 | 50 | |