Popular keywords: Electric hoist, European style crane, lightweight customized crane

Product Introduction Using high-strength magnesium aluminum alloy material, the chain is made of high-strength specially made alloy steel material. The ring chain lever hoist is made of aluminum alloy ring chain lever hoist, also known as chain tightener or hand chain tightener....

400-966-5869

Product Introduction

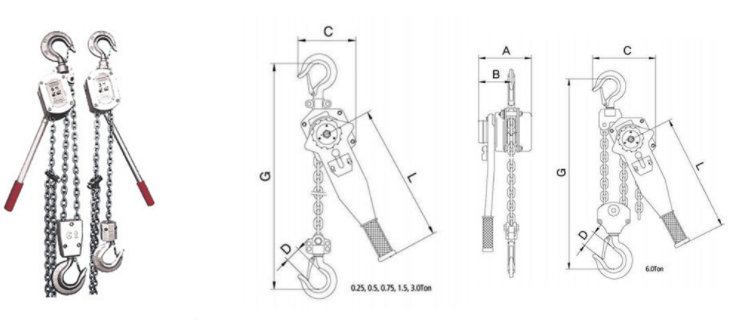

Using high-strength magnesium aluminum alloy material, the chain is made of high-strength specially made alloy steel material. The ring chain lever hoist is made of aluminum alloy ring chain lever hoist, also known as chain tightener or hand chain tightener. The main body is made of imported aluminum alloy from Japan.

The aluminum alloy ring chain lever gourd has a beautiful appearance, greatly reducing its own weight and making it easy to carry. Aluminum alloy chain hoist is mainly used for lifting and traction. Like other chain hoists, aluminum alloy chain hoist has excellent performance and reliable operability, and can still be used without power supply.

Advantages of aluminum alloy ring chain lever gourd:

1. The high-strength and high plasticity aluminum alloy box greatly enhances the strength of the product while maintaining lightweight weight.

2. The two-stage speed change and short handle make operation more effortless.

3. The handle can rotate 360 ^ and provide multiple operating modes in limited space.

4. The sprocket mechanism that can rotate freely in neutral ensures that the chain can pass quickly and easily.

5. The fully enclosed and automatically adjustable braking system effectively eliminates impact while keeping the brakes clean and dry, making work safer and more reliable. Capable of controlling the position of heavy objects through micro movement.

Application fields of aluminum alloy chain hand plate gourd:

The product is applied to mechanical equipment in infrastructure construction projects such as electricity, ships, automobile manufacturing, construction, highways, bridges, metallurgy, mines, slope tunnels, and shaft treatment and protection.

| Rated traction (T) |

Standard traction length (m) |

Test load (kn) |

Hand force at full load (n) |

Lifting chain diameter (mm) |

Hoisting chain rows | Minimum distance between two hooks (mm) |

Product net weight (kg) |

Main dimensions (mm) | Traction length per increase m Added weight |

||||||

| A | B | C | D | E | (I) | ||||||||||

| 3 | 1.5 | 36.8 | 340 | 7 | 1 | 420 | 9.5 | 180 | 106 | 132 | 450 | 31 | 45 | 1.05 | |

| 6 | Revocation | 1.5 | 73.5 | 360 | 7 | 2 | 500 | 16.5 | 180 | 106 | 155 | 450 | 45 | 24 | 2.18 |

| Hook type | 1.5 | 73.5 | 360 | 7 | 2 | 535 | 16.3 | 180 | 106 | 175 | 450 | 39 | 55 | 2.18 | |